Steel 1.2714 - PWM

1.2714 - PWM steel:

high performance die steel.

What?

1.2714 – PWM steel is the traditional high performance die steel with good toughness and high tempering and compression strength.

Material properties

Properties of steel type 1.2714 – PWM

- Good toughness.

- High tempering.

- High compression strength.

Application

The most common applications for steel type 1.2714 – PWM are:

- Forging dies for all kinds of steel forming.

- Hammer and press saddles.

- Jaws in cutting machines.

- Tools for the extrusion industry.

- Press die holder.

- Linings and support tools.

- Tool brackets.

- Impression dies of all kinds for all light metals and their alloys.

- Piercer shafts and hole pots for steel pipe bloom manufacturing.

Physical properties of 1.2714 - PWM

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.0 | 12.5 | 13.3 | 14.0 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 36.0 | 36.5 | 36.0 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 7.8 | |||

| Temperature in °C | 20 | |||

| E module in GPa | 215 |

Heat treatment

| Soft annealing | Temperature: 740 – 760 °C, 6 – 8 hrs. |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 250 HB | |

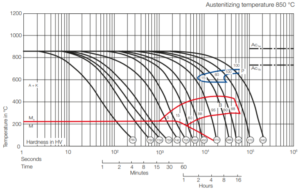

| Hardening | Temperature: 850 – 880 °C in Oil/polymer, 880 – 900 °C in blast air |

| Cooling Cooling must be interrupted at approx. 150 °C or vacuum hardening | |

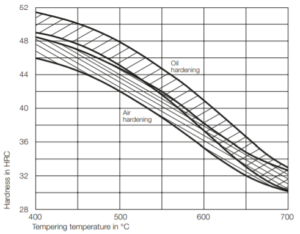

| Tempering | Temperature: 400 – 700 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible under conditions |

| Preheat before use | Temperature: 150 – 350 °C |