Steel 1.2316 - CMR

1.2316 - CMR steel:

heat-treatable corrosion-resistant steels.

What?

1.2316 – CMR steel belongs to the group of heat-treatable corrosion-resistant steels. This resistance against corrosion is achieved through the high Cr and low C content. CMR is suitable for the processing of chemically particularly aggressive plastics such as PVC. Chrome-plating is unneccessary. CMR has a good polishability. Delivery condition: Tempered, strength as required between 800 and 1100 MPa.

Material properties

Properties of steel type 1.2316 – CMR

- Corrosion-resistant.

- processing of aggressive plastics.

- Chrome-plating is unneccessary.

- Good polishability.

Application

The most common applications for steel type 1.2316 – CMR

Injection moulds and extrusion tools in the processing of plastics which can release corrosive materials.

Physical properties of 1.2316 - CMR steel

| Temperature in °C | 20-100 | 20-400 | 20-600 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 10.5 | 11.4 | 11.9 |

| Temperature in °C | 20 | ||

| Thermal conductivity in W/m x K | 20.7 | ||

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.7 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 215 |

Heat treatment

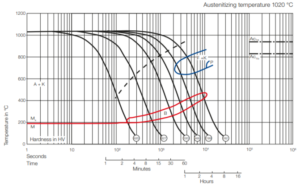

| Hardening | Temperature: 1020 – 1050 °C |

|---|---|

| Koeling: interrupt oil cooling at 250 °C | |

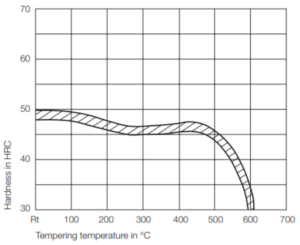

| Tempering | Temperatuur: 580 – 620 °C Avoid temperature range of the secondary hardness maximum. |

| Hardness: see tempering curve | |

| Nitriding | Possible, temper correspondingly. The corrosion resistance is reduced by such a treatment. |