Steel Q10

Q10 steel:

toughness, strength and thermical shock resistant

What?

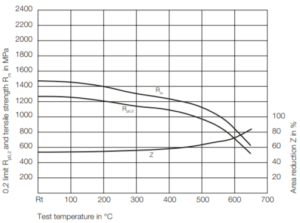

Q10 is a Cr-Mo-V alloyed hot work tool steel with very good high temperature strength characteristics and maximum toughness.

This grade is also characterised by good thermal shock resistance.

Kenmerken

- Maximum toughness.

- Strength by high temperature.

- Thermical schock resistance.

Toepassing

- Extrusion presses with very long lifetime with heavy duty inner linings and press stems

- Drop forging

- Hot forming.

Physical properties of Q10

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 10.3 | 11.3 | 12.6 | 13.0 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 29.8 | 31.0 | 31.4 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 7.8 | |||

| Temperature in °C | 20 | |||

| E module in GPa | 214 |

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: soft furnace cooling | |

| Hardness: max. 220 HB | |

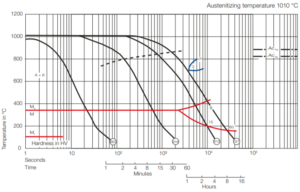

| Hardening | Temperature: 1010 – 1020 °C |

| Cooling Interrupt oil or polymer cooling at 230 – 280 °C or vacuum hardening | |

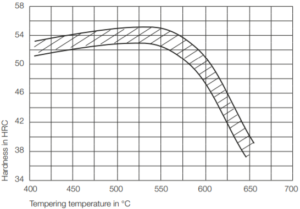

| Tempering | Temperature: 540 – 680 °C |

| Hardness: see tempering diagram | |

| Nitriding | Possible |

| Preheat before use | Temperature 150 – 350 °C depending on area of application |