Steel 1.2678 - HWD

1.2678 - HWD steel

high temperature strength and tempering resistance

What?

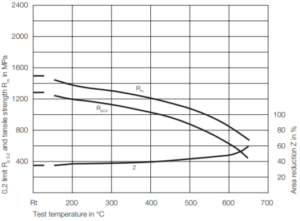

Because of its balanced composition, steel type 1.2678 – HWD is a hot-work tool steel with maximum high temperature strength and tempering resistance with particularly high hot wear resistance. Compared to MA, HWD does not tend towards hot embrittlement.

Material properties

Properties of steel type 1.2678 – HWD

- Maximum high temperature strength.

- Good tempering resistance.

- High hot wear resistance.

- Not tend towards hot embrittlement.

- Water cooling is not possible.

Application

the most common applications for steel type 1.2678 – HWD are:

- Extrusion press dies for brass.

- Die holders for heavy metal processing.

- Die-casting dies for heavy metals and relatively thin-walled cast pieces, heavy duty cores, which lie in the casting stream, light metal casting.

- Impression dies, especially mandrel inserts for hot pressing of heavy metals.

- Small die inserts and warm extrusion dies in steel forming.

Physical properties of 1.2678 - HWD

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.6 | 12.0 | 12.5 | 13.0 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 24.0 | 28.5 | 31.7 |

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 240 HB | |

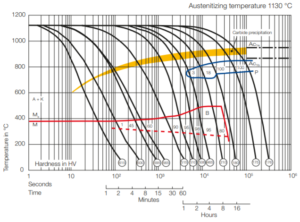

| Hardening | Temperature: 1130 – 1180 °C |

| Cooling Air, warm bath of approx. 540 °C, Oil/polymer; Interrupt oil or polymer cooling at 250 – 300 °C or vacuum hardening | |

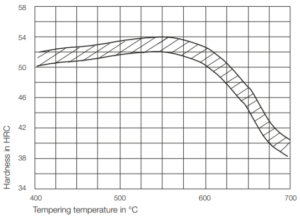

| Tempering | Temperature: 580 – 750 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 200 – 400 °C |