FSR steel

Steel FSR:

temper resistance and wear resistance .

What?

FSR steel is a cold work tool steel based on 12% Cr. The other alloy elements give FSR the necessary temper resistance and wear resistance.

Compared to a similarly used high-speed steel such as type HS6-5-2C, FSR is characterised by better toughness with equivalent performance.

Material properties

- Better toughness.

- Wear resistance.

Application

- Cutting tools with particular wear resistance in the processing of siliconised or austenitic sheet metal or hardened strip steel, precision punching tools.

- Cold extrusion tools.

- Threaded rolling tools.

- Broaches.

- Extruder screws.

Physical properties of FSR

| Temperature in °C | 20-100 | 20-200 | 20-400 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 10.6 | 12.0 | 13.0 |

| Temperature in °C | 20 | ||

| Thermal conductivity in W/m x K | 29.9 |

Heat treatment

| Soft annealing | Temperature: 800 – 850 °C |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 300 HB | |

| Hardening | Temperature: 1150 – 1180 °C |

| Cooling Hot strip from 450 – 550 °C or oil, interrupt oil cooling at approx. 400 °C | |

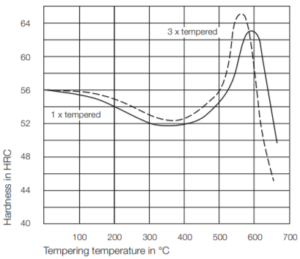

| Tempering | Temperature: 540 – 550 °C |

| Hardness: see tempering curve | |

| Nitriding | possible, temper correspondingly |