Steel 1.2888 - RM10Co

1.2888 - RM10Co steel:

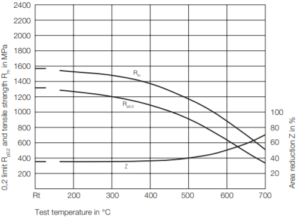

extremely high tempering resistance

What?

1.2888 – RM10Co steel is a high-alloy special steel with extremely high tempering resistance. RM10Co is suitable for particular requirements in respect of hightemperature wear resistance and resistance against molten metals.

Material properties

Properties of steel type 1.2888 – RM10Co

- Extremely high ontlaatbestendigheid.

- Hightemperature wear resistance.

- Resistance against molten metals.

- Water cooling is not possible.

Application

The most common applications for steel type 1.2888 – RM10Co are:

- Tools for extrusion presses such as press dies for steel and heavy metal processing, as well as spider tools and frame tools for processing

copper and its alloys.

- Mould plates for brass pressure die-casting.

- Valves.

- Cores and filling sets.

- Filling sets in magnesium die casting in hot chamber machines.

- Hot extrusion presses for dies.

- Punch for steel forming.

Physical properties of 1.2888 - RM10Co steel

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.3 | 12.2 | 12.6 | 12.6 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 20.5 | 24.2 | 27.5 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 8.08 | |||

| Temperature in °C | 20 | |||

| E module in GPa | 215 |

Heat treatment

| Soft annealing | Temperature: 840 + 760 °C |

|---|---|

| Cooling: slof furnace cooling | |

| Hardness: max. 320 HB | |

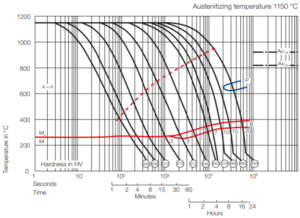

| Hardening | Temperature: 1100 – 1150 °C |

| Cooling Hot strip of approx. 540 °C, Air or oil/polymer; Interrupt oil or polymer cooling at 250 – 300 °C or vacuum hardening | |

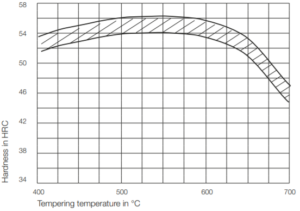

| Tempering | Temperature: 600 – 750 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |